AR in Manufacturing transforms production with real-time insights, predictive maintenance, and immersive training. Enhancing efficiency, safety, and inclusivity, it enables hyper-personalized workflows, reduces errors, and empowers manufacturers to innovate, optimize operations, and stay competitive in a rapidly evolving industry.

Introduction to AR in Manufacturing

The manufacturing industry is experiencing a profound shift as AR in Manufacturing becomes increasingly integrated into production environments. Traditional processes, which relied heavily on manual supervision and static instructions, are now being augmented with immersive technology that offers real-time guidance and visualization. Companies across sectors are recognizing the potential of augmented reality to enhance efficiency, reduce errors, and transform the way products are designed, assembled, and maintained.

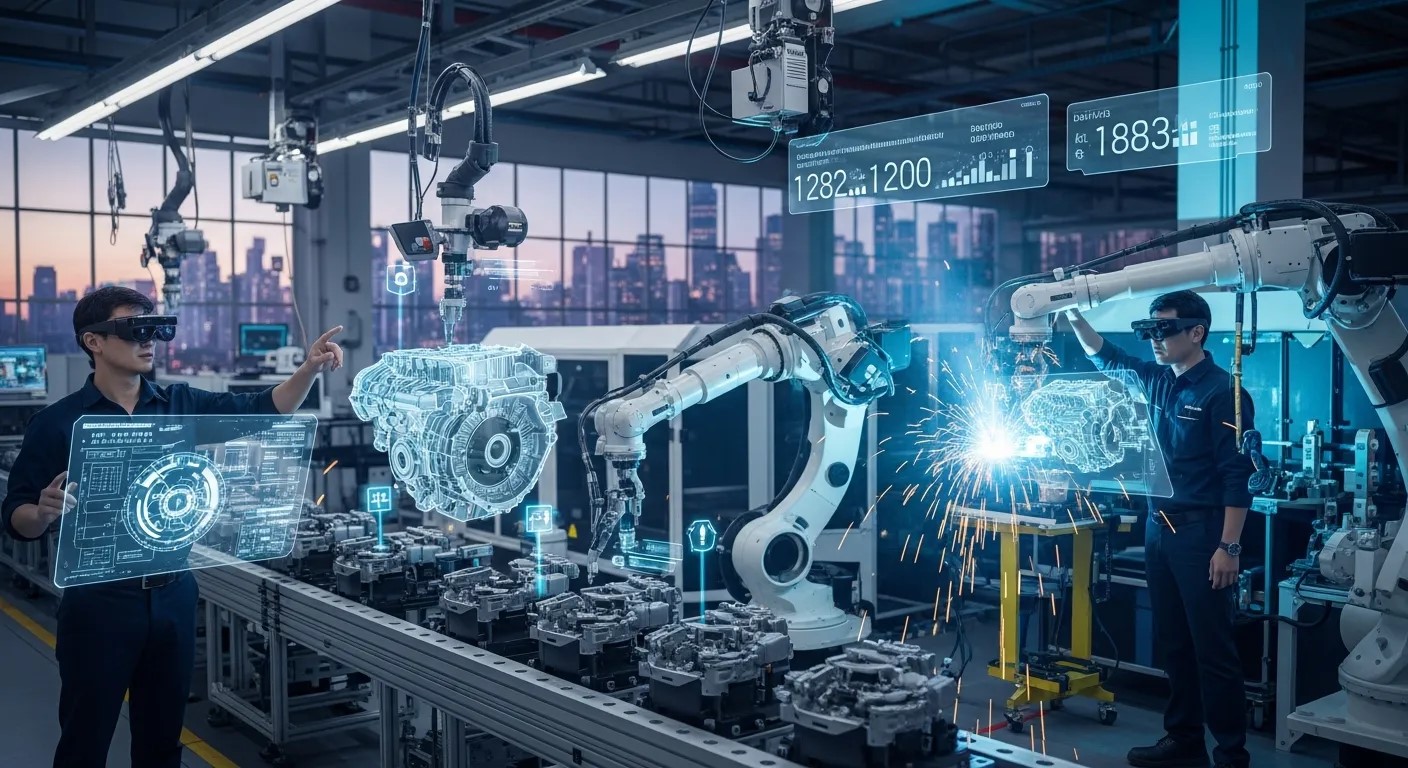

Unlike conventional software tools, AR provides a layered digital interface directly on physical equipment, allowing operators to visualize complex assembly instructions without diverting their attention from the task at hand. This hands-free interaction ensures a smoother workflow, reduces downtime, and promotes safer operations, particularly in high-risk industrial environments. By adopting AR in manufacturing, businesses can bridge the gap between digital planning and physical execution, ensuring that every step in the production line is optimized for both speed and precision.

How AR is Transforming Production Processes

The integration of AR in manufacturing is no longer a futuristic concept—it is actively reshaping modern production strategies. From assembly lines to quality control, AR solutions are providing real-time insights that enable smarter decision-making and streamlined operations.

Enhanced Visualization and Workflow Optimization

One of the primary advantages of implementing AR in manufacturing is the ability to visualize complex systems before physically interacting with them. Operators can see a holographic overlay of machinery components, which reduces the likelihood of assembly errors. By simulating various scenarios in a digital layer, manufacturers can identify potential bottlenecks and optimize workflows before they occur. This approach not only improves efficiency but also supports more sustainable production by reducing material waste and energy consumption.

Additionally, AR-enabled tools can display step-by-step instructions tailored to each operator’s expertise level. This ensures that even new employees can perform intricate tasks accurately, which significantly reduces training time. Many organizations are now exploring inclusive AR solutions to ensure that augmented instructions are accessible to workers with varying physical abilities or technical knowledge, promoting inclusivity and operational consistency.

Real-Time Data and AR Intelligence

The true power of AR in manufacturing lies in its ability to integrate real-time data into everyday operations. Connected sensors, IoT devices, and advanced analytics allow AR platforms to deliver insights that were previously difficult to access. For instance, an operator wearing AR glasses can see live performance metrics of a machine, predictive maintenance alerts, or workflow adjustments without leaving the production floor.

By combining augmented reality with AR intelligence, manufacturers gain a competitive advantage, as decision-makers can respond instantly to anomalies or inefficiencies. This synergy between human intuition and digital augmentation ensures that production lines are both flexible and resilient, capable of adapting to changing demands while maintaining high quality standards.

Safety and Training Improvements

Safety remains a top priority in manufacturing, and AR in manufacturing is providing new avenues for proactive risk management. Interactive AR training modules allow employees to practice dangerous procedures in a controlled virtual environment before applying them in the real world. This immersive training method reduces workplace accidents and enhances overall operational confidence.

Moreover, AR can overlay hazard zones, alert workers to potential risks, and guide emergency responses in real time. When combined with AI-powered tools that analyze performance trends, manufacturers can continuously improve their safety protocols and ensure compliance with industry standards. Integrating AI-Personalized VR Narratives in training programs further enhances learning outcomes by delivering tailored experiences based on individual progress and comprehension levels.

AR-Driven Innovation Across Manufacturing Sectors

The impact of AR in Manufacturing extends across a wide range of industries, from automotive to consumer electronics, transforming the way production lines operate and products are delivered. By integrating AR into existing workflows, companies can create smart factories where every process, from assembly to quality assurance, is optimized through digital augmentation.

Automotive and Aerospace Industries

In the automotive sector, AR in Manufacturing is enabling engineers to overlay design schematics directly onto physical components, simplifying complex assembly processes. Technicians can identify misalignments or defects in real time, preventing costly errors before they escalate. Aerospace manufacturers are similarly leveraging AR to guide maintenance crews through intricate procedures, reducing aircraft downtime and ensuring compliance with rigorous safety standards.

Moreover, AR facilitates collaboration between geographically dispersed teams. Engineers in different locations can interact with the same 3D models, annotate issues, and propose solutions in real time, fostering innovation and reducing development cycles. By incorporating AI-Powered AR Decision systems, manufacturers can now make automated suggestions for adjustments or process optimizations based on historical data and real-time inputs, further accelerating production efficiency.

Consumer Goods and Electronics

For consumer electronics, precision and speed are crucial. AR in Manufacturing allows assembly operators to visualize circuits, component placements, and wiring paths without relying solely on traditional instruction manuals. This reduces errors and ensures consistent product quality across batches. Companies producing high-volume goods can now monitor operations via AR dashboards, identifying anomalies instantly and deploying corrective measures before they impact overall output.

AR also enhances prototyping and design testing. By overlaying digital prototypes onto physical models, designers and engineers can evaluate ergonomics, functionality, and aesthetics simultaneously. This iterative approach shortens development cycles and supports a culture of innovation within the manufacturing floor.

Industrial Equipment and Heavy Machinery

In industries involving heavy machinery, AR in Manufacturing has revolutionized maintenance and training. Field technicians can receive AR-guided instructions while interacting with large, complex equipment, eliminating the need for extensive reference manuals. This hands-on approach increases efficiency, reduces human error, and ensures safety in high-risk environments.

Predictive maintenance powered by AR further ensures that machines remain operational longer. By analyzing real-time performance metrics, operators can anticipate component failures and schedule timely interventions. The integration of AI-Powered AR Decision capabilities enables factories to automatically adjust workflows based on equipment health and production priorities, creating an agile and responsive manufacturing environment.

Benefits Across Sectors

Across all sectors, the adoption of AR delivers measurable benefits:

| Benefit | Description | Example |

|---|---|---|

| Efficiency | Streamlines workflows and reduces downtime | Automotive assembly line |

| Accuracy | Reduces errors and rework | Electronics soldering |

| Training | Shortens learning curves | Heavy machinery maintenance |

| Collaboration | Enables remote teams to work together | Global aerospace design |

| Predictive Insights | Optimizes operations using real-time data | Industrial equipment monitoring |

By strategically implementing AR, manufacturers are not only improving production metrics but also fostering a culture of continuous innovation. The combination of AR in Manufacturing and intelligent decision-making tools allows organizations to stay ahead of market demands while ensuring operational excellence.

Hyper-Personalization at Scale in Modern Manufacturing

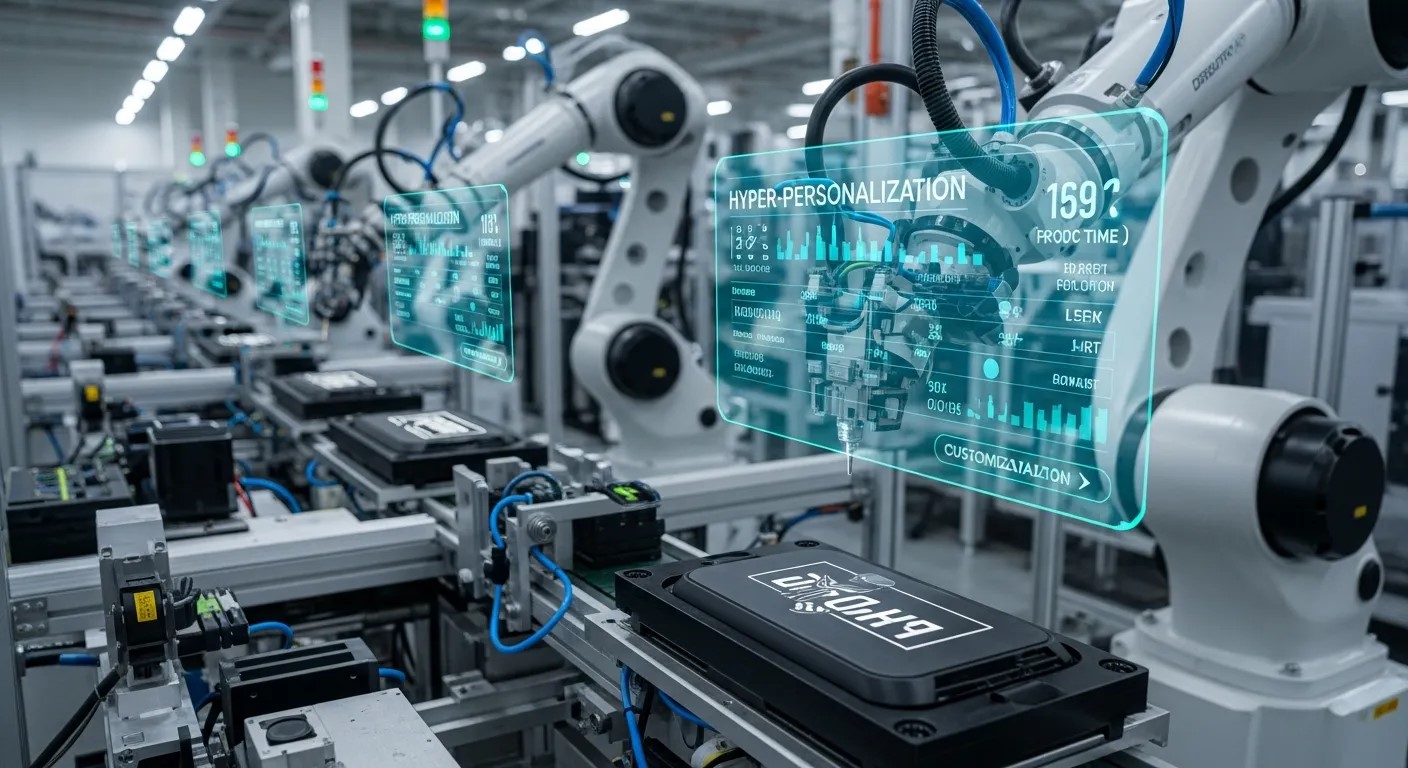

In today’s competitive industrial landscape, one-size-fits-all solutions no longer suffice. The adoption of AR in Manufacturing is empowering factories to implement hyper-personalization at scale, tailoring workflows, machine settings, and operator guidance to specific needs. By leveraging real-time data and AR overlays, production systems can adjust parameters dynamically, ensuring each batch meets precise specifications without compromising speed or efficiency.

Hyper-personalized AR experiences allow operators to access context-specific instructions, enhancing both productivity and accuracy. For instance, an assembly worker handling a complex component can receive step-by-step guidance unique to their skill level, reducing errors while accelerating the learning curve. This approach also allows companies to optimize resource allocation, as production adjustments can be automatically implemented based on machine performance, product type, and operator expertise.

Voice-Enabled Chatbot Support on the Production Floor

Another breakthrough in AR in Manufacturing is the integration of voice-enabled chatbot systems. These intelligent assistants allow operators to interact with AR platforms hands-free, retrieving instructions, machine diagnostics, or workflow updates in real time. By simply speaking commands, workers can minimize distractions, maintain safety, and improve operational speed.

Voice-enabled chatbots also support remote troubleshooting. Supervisors can provide guidance without physically visiting the production floor, while the chatbot captures and delivers real-time insights to management dashboards. Over time, these systems can learn from repeated interactions, anticipating operator needs and streamlining decision-making processes. The result is a fully connected production ecosystem that blends human expertise with digital augmentation.

Inclusive AR: Making Manufacturing Accessible

Equally important is ensuring that AR in Manufacturing solutions are inclusive and accessible to a diverse workforce. Inclusive AR design principles focus on creating interfaces that accommodate varying levels of technical literacy, physical ability, and language proficiency. This ensures that every operator can leverage AR tools effectively, regardless of prior experience or personal limitations.

For example, visual overlays can be adjusted for color blindness, text instructions can be simplified or converted into audio, and gesture-based controls can replace manual inputs for those with physical constraints. Inclusive AR practices not only improve workplace safety but also foster employee engagement and productivity, creating an environment where innovation is accessible to all.

Enhancing Employee Training with AR

AR-enabled training modules have become a cornerstone of modern manufacturing. Operators can practice complex procedures in a virtual layer before applying them in real-world scenarios, drastically reducing errors and boosting confidence. By integrating AI-Personalized VR Narratives, training programs adapt to each employee’s learning style, offering a tailored experience that reinforces retention and skill mastery.

Furthermore, these immersive training tools allow companies to scale education programs across multiple facilities without the need for additional instructors. This results in consistent training standards, faster onboarding, and a more competent workforce prepared to meet the demands of advanced manufacturing environments.

AR Intelligence, Predictive Maintenance, and the Future of Manufacturing

The modern manufacturing landscape is being reshaped by the integration of AR in Manufacturing, where digital overlays meet physical operations to create highly responsive, data-driven production environments. Factories are no longer isolated workspaces but dynamic ecosystems where operators, machines, and digital systems collaborate seamlessly. By embedding AR intelligence into production lines, manufacturers gain access to real-time monitoring, predictive analytics, and actionable insights, enhancing both efficiency and quality.

Real-Time Monitoring and AR Intelligence

One of the most significant advantages of AR in Manufacturing is the ability to monitor operations in real time. Operators wearing AR-enabled devices can view live data overlaid on machines, including performance metrics, temperature readings, and workflow progress. This instant visualization allows them to identify inefficiencies or anomalies before they escalate, ensuring continuous, uninterrupted production.

The integration of AR intelligence empowers supervisors to make faster, more informed decisions. For example, if a machine begins to operate outside optimal parameters, the system can highlight the issue directly in the operator’s field of view, suggesting corrective actions. This synergy between human expertise and digital augmentation not only improves operational precision but also fosters a proactive culture, reducing downtime and enhancing safety.

Predictive Maintenance: Reducing Downtime and Costs

Traditional maintenance in manufacturing often relies on scheduled checks or reactive interventions after equipment failure. AR in Manufacturing transforms this approach by enabling predictive maintenance, which leverages sensor data and AR overlays to detect early signs of wear or malfunction. Operators can follow step-by-step visual guidance to perform preventive maintenance tasks, reducing the likelihood of costly breakdowns.

Predictive maintenance enhances overall productivity by ensuring that machinery operates at peak efficiency. Combined with AI-powered analysis, AR can suggest maintenance schedules based on usage patterns, environmental conditions, and historical performance. The result is a resilient production line that anticipates problems rather than reacting to them, ultimately saving time, money, and resources.

Supply Chain Optimization with AR

Efficient supply chains are critical for modern manufacturing, and AR in Manufacturing plays a crucial role in optimizing these networks. AR can overlay warehouse layouts, inventory levels, and logistical pathways, allowing operators to locate components quickly and reduce processing errors. Real-time supply chain insights enable manufacturers to predict potential delays, adjust schedules, and reroute resources to maintain smooth production.

By visualizing the entire supply chain through AR dashboards, managers gain a holistic view of operations, improving decision-making and coordination across departments. This approach ensures that production remains agile, responsive, and capable of meeting customer demands while minimizing waste and cost.

Key Benefits and Applications of AR in Manufacturing

| Application Area | Description | Impact |

|---|---|---|

| Real-Time Monitoring | Overlay machine performance and workflow data | Reduces errors, improves efficiency |

| Predictive Maintenance | Visual guidance for proactive equipment care | Minimizes downtime, lowers costs |

| Training & Onboarding | AR-guided immersive training for operators | Faster learning, higher retention |

| Supply Chain Optimization | Visualized inventory and logistics management | Agile, efficient operations |

| Safety & Compliance | Hazard overlays and safety alerts | Reduces accidents, ensures compliance |

| Hyper-Personalization | Customized AR instructions per operator | Boosts productivity and accuracy |

| Remote Collaboration | Shared 3D models for global teams | Faster problem-solving, innovation |

Hyper-Personalization and Operator Experience

Another transformative aspect of AR in Manufacturing is hyper-personalization at scale. Production systems can now adjust instructions, workflows, and machine settings based on individual operator profiles, experience levels, or current tasks. This approach ensures every worker receives the guidance needed to perform at their best, reducing errors and accelerating throughput.

When combined with immersive training tools like AI-Personalized VR Narratives, operators experience a tailored learning environment that adapts in real time to their performance. Such personalization fosters engagement, increases confidence, and ensures a highly skilled workforce capable of operating complex machinery efficiently.

Voice-Enabled Chatbots: Hands-Free Assistance

Voice-enabled chatbots integrated into AR systems are enhancing the production floor experience. Workers can access instructions, troubleshoot issues, or request data without pausing their tasks. This hands-free approach improves safety, maintains workflow continuity, and allows supervisors to guide operations remotely. Over time, these systems learn from repeated interactions, providing predictive support that anticipates operator needs and enhances overall efficiency.

Inclusive AR: Accessibility for All Operators

Inclusive design is essential for modern factories. Inclusive AR ensures that augmented reality tools are usable by workers with diverse abilities, language preferences, and technical skills. Features like adjustable visual overlays, audio instructions, and gesture-based controls create a production environment that is accessible to everyone. Inclusive AR not only improves productivity but also fosters a collaborative and equitable workplace culture.

The Future of AR in Manufacturing

Looking forward, AR in Manufacturing will become the cornerstone of the smart factories of tomorrow. Advances in AR intelligence, predictive analytics, AI-powered decision-making, and immersive training will enable factories to operate autonomously while still keeping humans in the loop.

Future AR systems will:

- Provide real-time insights across global production networks

- Automate routine tasks and maintenance recommendations

- Deliver hyper-personalized operator experiences

- Enable fully remote collaboration for design and troubleshooting

Manufacturers that embrace these technologies early will achieve higher productivity, lower operational costs, and superior product quality, ensuring competitiveness in a rapidly evolving industrial landscape.

Conclusion

The integration of AR in Manufacturing is reshaping the industrial landscape, enabling smarter workflows, enhanced safety, and greater operational efficiency. By leveraging AR in Manufacturing, companies can implement predictive maintenance, real-time monitoring, and hyper-personalized training, ensuring higher productivity and reduced errors. Embracing these innovations positions manufacturers to stay competitive, innovate faster, and build a resilient, future-ready production environment.

Frequently Asked Questions (FAQ)

What is AR in Manufacturing?

AR in Manufacturing refers to the use of augmented reality technology to enhance production processes. It overlays digital information onto physical equipment, helping operators with real-time guidance, visualization, and error reduction.

How does AR improve efficiency in manufacturing?

By providing step-by-step instructions, real-time monitoring, and predictive insights, AR in Manufacturing helps reduce errors, minimize downtime, and streamline workflows, making operations faster and more accurate.

Can AR in Manufacturing help with employee training?

Yes. Immersive AR training modules, sometimes combined with AI-Personalized VR Narratives, allow employees to practice complex tasks safely, shorten learning curves, and gain hands-on experience without risking production errors.

What industries benefit most from AR in Manufacturing?

Automotive, aerospace, consumer electronics, and heavy machinery industries are among the biggest beneficiaries. Any sector with complex assembly, high safety requirements, or detailed production processes can leverage AR for efficiency and accuracy.

Does AR support predictive maintenance in manufacturing?

Absolutely. AR in Manufacturing allows operators to visualize real-time machine data, detect early signs of wear, and perform predictive maintenance, reducing unexpected downtime and saving operational costs.

How does AR in Manufacturing contribute to inclusivity?

Inclusive AR ensures that augmented instructions and interfaces are accessible to workers of varying abilities and technical skill levels. Features like adjustable visual overlays, audio instructions, and gesture-based controls create an equitable work environment.

What is the future outlook for AR in Manufacturing?

The future involves greater integration of AR intelligence, predictive analytics, hyper-personalization at scale, and voice-enabled support systems. AR in Manufacturing will continue to enhance productivity, safety, and innovation across industries.