Factory floors today look vastly different than they did even five years ago. The introduction of augmented reality (AR) has transformed industrial spaces into high-tech environments where physical and digital worlds merge.

Workers now wear smart glasses that overlay critical information directly into their field of vision. This breakthrough has changed how manufacturing and maintenance tasks are performed forever.

The impact of industrial AR applications cannot be overstated. Companies report efficiency improvements of 25-40% when implementing these solutions properly.

AR in Manufacturing Processes

Manufacturing processes benefit tremendously from AR integration. Assembly line workers can see step-by-step visual instructions projected directly onto the components they’re working with.

Gone are the days of constantly referencing paper manuals or computer screens. Information now appears exactly where and when needed, keeping hands free for actual work.

Error rates drop dramatically when using AR guidance. One automotive manufacturer noted a 38% reduction in assembly errors after implementing AR headsets on their production line.

Training and Skill Development

Training new staff becomes much more intuitive with AR. New hires can learn complex assembly procedures in roughly half the time compared to traditional training methods.

The technology adapts to individual learning paces. Visual indicators show when actions are performed correctly, providing immediate feedback that reinforces proper techniques.

Maintenance and Remote Assistance

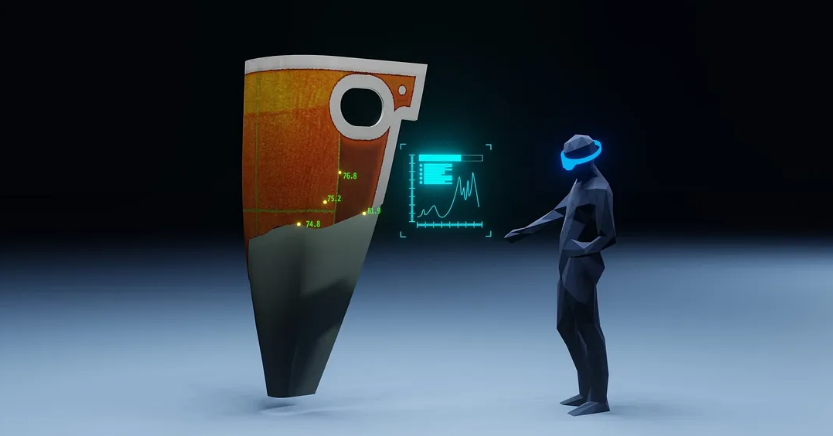

Maintenance operations have seen perhaps the most dramatic benefits from AR adoption. Technicians approaching complex machinery can immediately see diagnostic information overlaid on specific components.

AR systems connect to industrial IoT sensors to display real-time performance data. Temperature readings, vibration analysis, and operational metrics become visible directly on the equipment being serviced.

Experienced technicians can remotely guide on-site workers through complex repairs using shared AR environments. This “see what I see” capability from RemoteSpark has proven invaluable during pandemic-related travel restrictions.

Warehouse and Logistics Applications

Warehouse operations have likewise been transformed. AR-equipped workers receive optimal picking paths and product locations directly in their field of vision, reducing travel time by up to 30%.

Logistics managers at Industrial AR Today report that pick accuracy improves by 25% when using AR guidance systems compared to traditional methods.

Quality control procedures benefit from AR overlays that highlight tolerance specifications. Inspectors can see precisely where measurements need to be taken and what acceptable ranges are.

Implementation Challenges

Implementation challenges exist, of course. Industrial environments can be harsh on sensitive electronics. Dust, moisture, and electromagnetic interference must all be addressed for reliable operation.

Battery life remains a concern for wearable AR devices in industrial settings. Workers need solutions that last through entire shifts without interruption.

At AR Marketing Tips, we’ve documented dozens of successful industrial AR deployments and found that proper planning addresses most common implementation pitfalls.

Integration with existing systems presents another challenge. AR solutions must connect seamlessly with enterprise resource planning (ERP) software and manufacturing execution systems.

ROI and Business Benefits

Return on investment calculations consistently favor AR adoption. Though initial implementation costs may seem high, the productivity gains, error reduction, and training improvements deliver payback typically within 12-18 months.

Safety improvements represent an often-overlooked benefit. AR can highlight hazardous areas, display safety procedures during emergencies, and ensure proper lockout-tagout sequences are followed.

Future Trends in Industrial AR

Future developments will likely include more autonomous functions. AR systems will increasingly suggest maintenance based on predictive analytics rather than just displaying information.

The industrial metaverse concept is gaining traction. Virtual replicas of entire factories allow for simulation and planning before physical changes are implemented.

Companies hesitant to adopt industrial AR risk falling behind competitors who embrace this technology. The productivity and quality advantages are simply too significant to ignore.

For manufacturing and maintenance operations seeking competitive advantage, augmented reality has moved from experimental technology to essential tool.

The question for industrial operations is no longer whether to implement AR, but how quickly they can deploy it across their facilities.